Here is the article with the requested clean-up and enhancements:

Cannabis Distillate Production: From Crude Oil to Pure Cannabinoids

The cannabis industry has evolved rapidly over the last decade, expanding far beyond traditional flower consumption into an impressive array of refined products. Among these, cannabis distillate stands out as one of the most versatile and potent forms of cannabis extract available. With a purity often exceeding 90% cannabinoids, distillate transforms the raw, sticky oil extracted from cannabis plants into a clean, translucent substance that delivers consistent potency and application flexibility.

Cannabis distillate is a type of extract that has been stripped of all materials and compounds except for one specific cannabinoid—most commonly THC or CBD. Unlike crude cannabis oil—which contains a complex mixture of cannabinoids, terpenes, lipids, and plant waxes—distillate undergoes a complex refinement process that isolates a single cannabinoid in its purest form. This makes it ideal for a variety of uses, from the foundation of edibles, topicals, and tinctures, to a key ingredient in vape cartridges and concentrates.

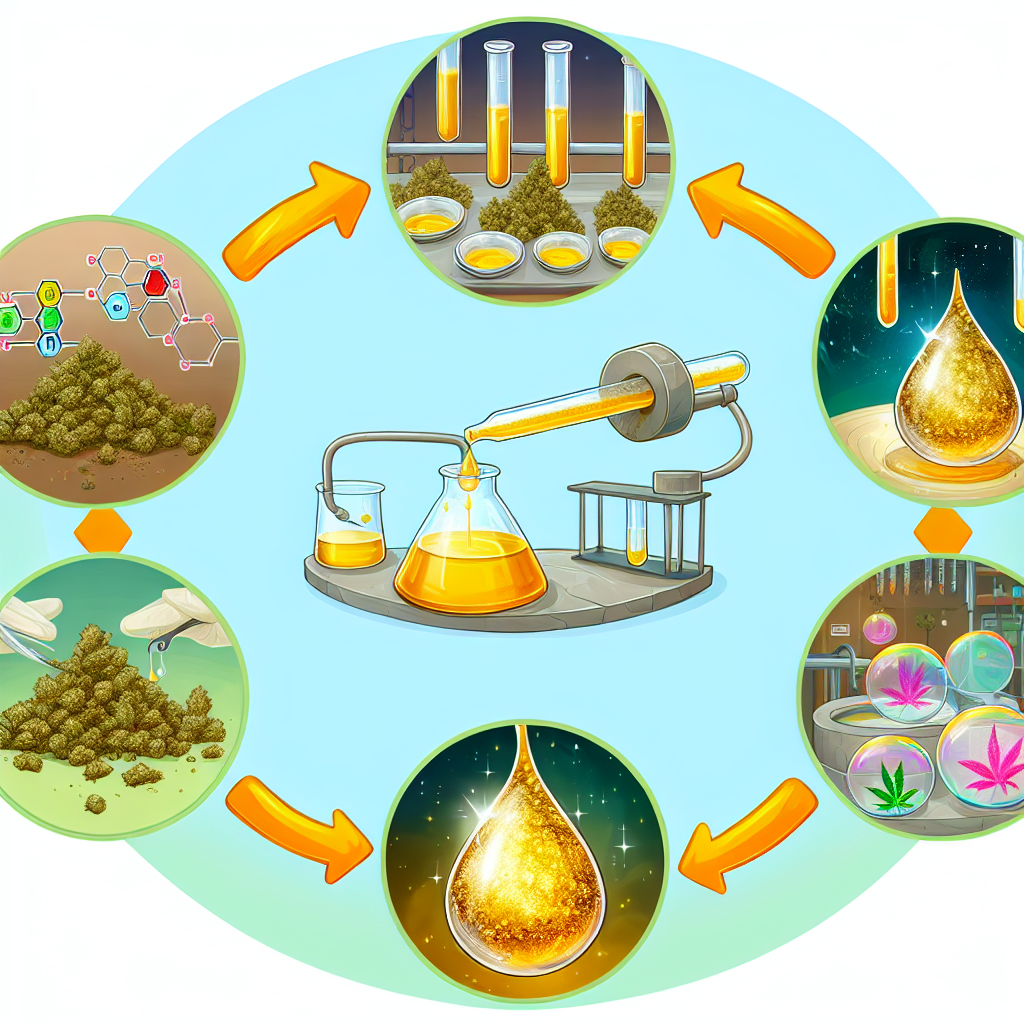

Unlocking Purity: How Science Turns Crude Extract into Pure Cannabis Gold

The production process of cannabis distillate typically involves several major steps: extraction, winterization, decarboxylation, and distillation. Each step eliminates undesirable elements such as chlorophyll, waxes, fats, and residual solvents, pushing the oil’s purity level to the highest standard. This scientific process draws from methodologies established in pharmaceutical chemistry and food production, utilizing techniques like short-path distillation to isolate beneficial compounds from unwanted constituents.

The first phase begins with crude oil extraction, commonly achieved via hydrocarbon (e.g., butane), ethanol, or supercritical CO₂ extraction. This raw oil still contains a host of undesirable organic components that would impair the purity and safety of the final product. Winterization is then implemented to filter out waxes and fats, followed by decarboxylation to convert non-psychoactive cannabinoid acids into their active forms.

Finally, the now-active extract is subjected to the distillation process, typically using short-path or wiped-film distillation units. These systems heat the extract under vacuum pressure to boil off cannabinoids at lower temperatures, preventing degradation and maximizing potency. Research has shown that cannabinoid recovery rates can exceed 95%, with purity levels consistently reaching above 90% for both THC and CBD distillates.

Safety First: Why Testing and Clean Production Are Crucial for Cannabis Distillates

Another critical factor in distillate production is the removal of residual solvents and pesticides. Because distillates are often consumed without combustion, there is less destructive filtration from heat, and ensuring the final product is devoid of harmful compounds is non-negotiable.

Producing medical-grade cannabis distillate also involves quality assurance protocols like high-performance liquid chromatography (HPLC) and gas chromatography–mass spectrometry (GC-MS) for confirming cannabinoid profiles and contaminant levels. Labs are now required in most legal jurisdictions to provide certificates of analysis (COAs) that validate these parameters for consumer safety and regulatory compliance.

Beyond THC & CBD: Reintroducing Terpenes for Custom Cannabis Experiences

Although cannabis distillate lacks natural terpenes after refinement, modern producers use selective terpene formulations or cannabis-derived terpenes to bring back strain-specific effects and flavors. This reintroduction generates hybrid products that combine the purity of distillate with the entourage effect believed to amplify cannabis’ therapeutic potential through synergistic interactions among various phytochemicals.

The Future of Cannabis: Distillates Pave the Way for Innovation and Integrity

Cannabis distillates are unlocking new avenues for precision, purity, and performance in the evolving weed ecosystem. From standardized medical dosing to innovative recreational products, distillate production exemplifies how science is elevating cannabis beyond stigma into a realm of legitimate pharmacology and safe consumer use. As extraction technologies improve and demand rises, expect cannabis distillates to remain at the forefront of innovation—delivering potent, predictable effects in their purest possible form.

Summary:

Cannabis distillate is a highly refined cannabis extract that isolates a single cannabinoid, such as THC or CBD, to over 90% purity. The complex production process involves extraction, winterization, decarboxylation, and distillation, transforming the raw plant material into a clean, consistent, and versatile product. Safety and quality testing are crucial, and producers can also reintroduce terpenes to create customized experiences. As the cannabis industry evolves, distillates are poised to drive innovation and integrity in both medical and recreational markets.

References:

[1] Molecules Journal – Wiped-Film Distillation Study: https://www.mdpi.com/1420-3049/25/4/906

[2] Frontiers in Pharmacology – Cannabis Analysis & Safety: https://www.frontiersin.org/articles/10.3389/fphar.2021.620477/full

[3] British Journal of Pharmacology – Entourage Effect: https://bpspubs.onlinelibrary.wiley.com/doi/full/10.1111/j.1476-5381.2011.01238.x