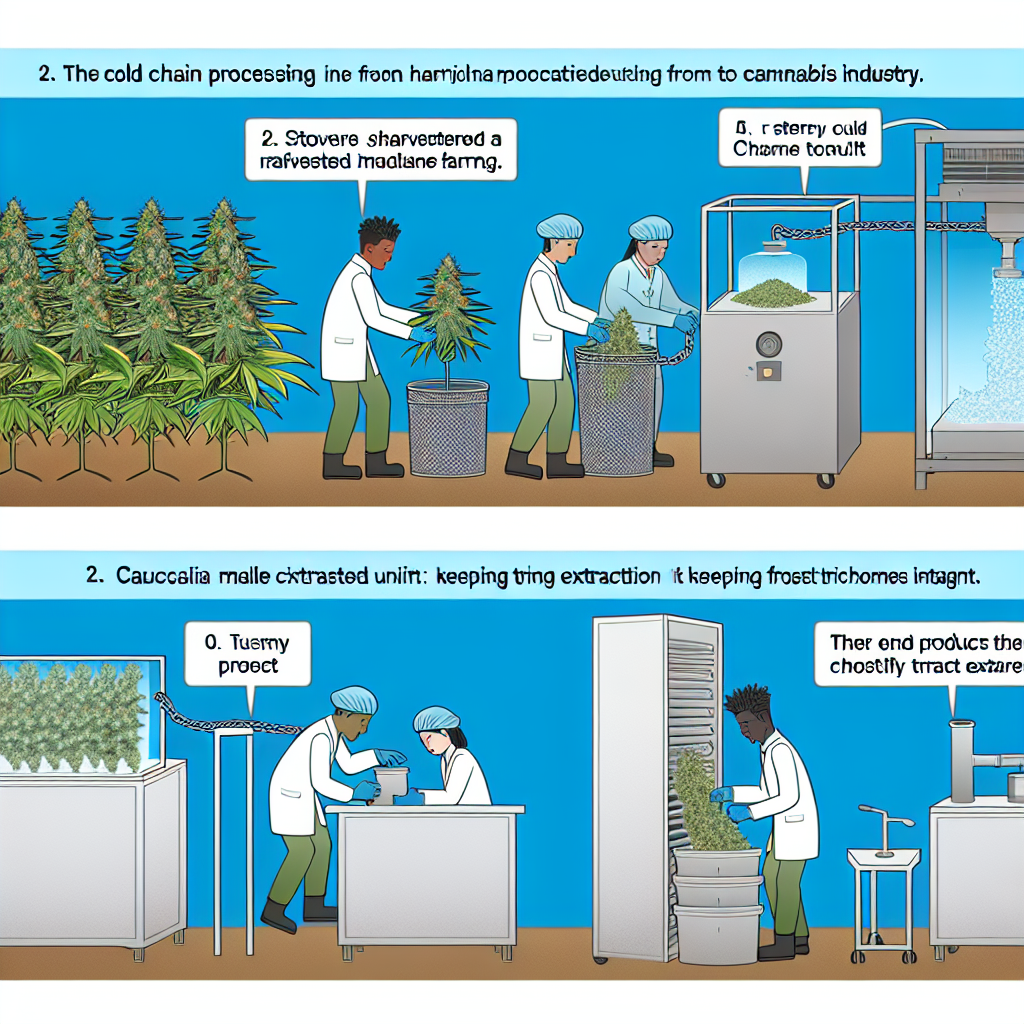

Cold Chain Processing – Maintaining Trichome Integrity from Harvest to Extraction

Introduction

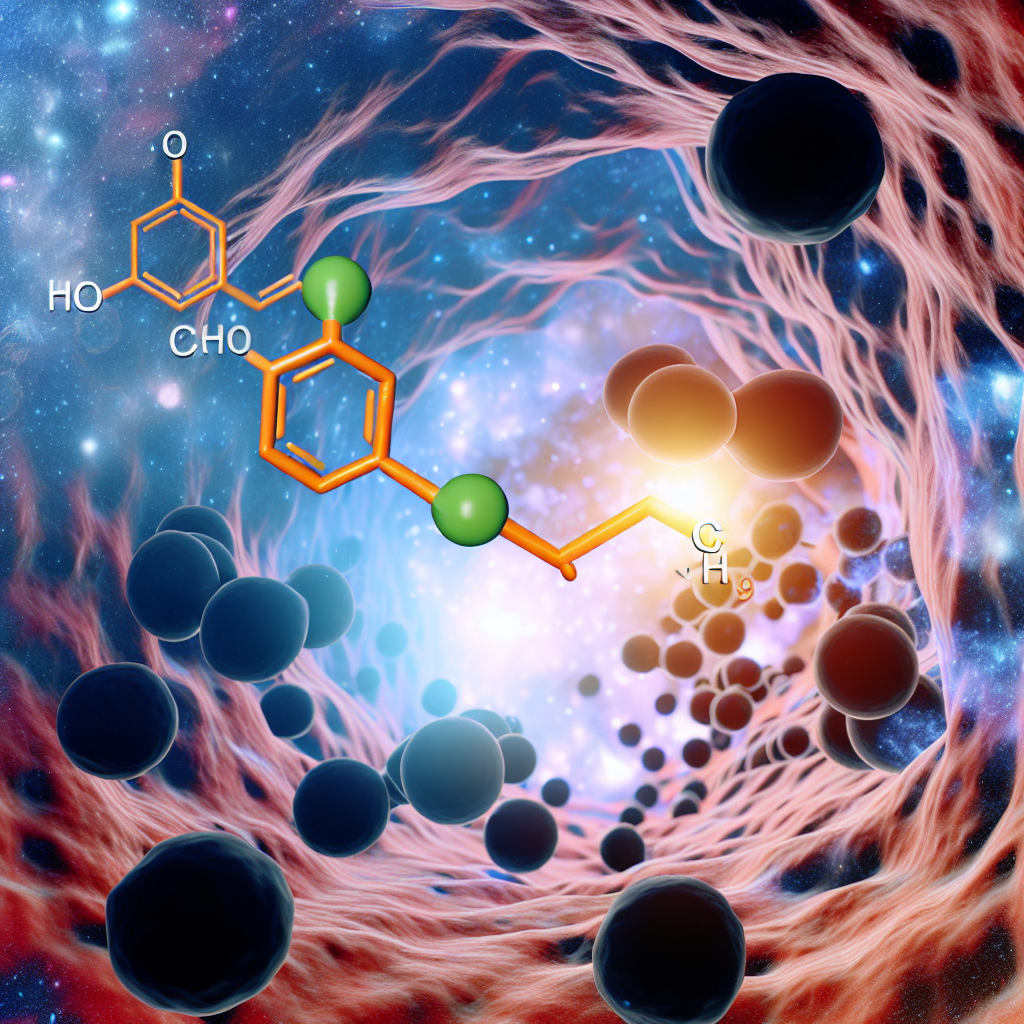

In the ever-evolving cannabis industry, maximizing the quality and potency of the final product is a critical goal for cultivators, extractors, and manufacturers. One key element—often underestimated—is the preservation of trichomes: the tiny glandular structures that contain the plant’s valuable compounds such as cannabinoids, terpenes, and flavonoids. These sensitive structures are susceptible to degradation from light, oxygen, heat, and physical agitation.

What is Cold Chain Processing?

Cold chain processing is a temperature-controlled supply chain system that preserves the quality of cannabis biomass post-harvest by minimizing exposure to environmental stressors. The goal is to maintain trichome integrity and preserve the full spectrum of chemical compounds during transport, storage, and extraction.

Unlike traditional methods that involve drying and curing the plant at room temperatures, this method involves flash-freezing the harvested plant within hours—typically at temperatures around -20°C or lower. By doing so, it effectively locks in the plant’s living state, along with its cannabinoid and terpene profiles, which would otherwise deteriorate under normal conditions.

The process requires specialized freezers, handling protocols, and insulated transport units. Though it demands more logistical planning and upfront investment, the resulting high-quality cannabis extracts such as live resin, live rosin, and full-spectrum extracts command premium market value and consistently outperform conventionally processed products in both quality and potency.

Key Benefits of Cold Chain Processing

Cold chain systems serve as a game-changer for serious cannabis professionals. Here’s why:

- Preservation of Cannabinoid and Terpene Profiles: Flash freezing halts enzymatic degradation and oxidation, protecting the most sensitive volatile compounds.

- Superior Product Quality: Extracts derived from fresh-frozen cannabis are richer in flavor, aroma, and potency.

- Consistency in Batch-to-Batch Production: Cold chain workflows reduce variability in extraction results, helping meet strict compliance requirements.

- Higher Market Value: Cold chain-produced products can be marketed as artisan-grade, often fetching higher price points and fostering brand loyalty.

Scientific Support and Industry Validation

Numerous scientific studies emphasize the importance of cold preservation in retaining the integrity of cannabis compounds. A pivotal study titled “Volatile Organic Compound Emissions from Cannabis Drying and Curing” published in Frontiers in Plant Science (2021) demonstrated that terpene loss begins at temperatures as low as 20°C. The study found massive degradation during air drying techniques that could be avoided through freezing.

Extraction companies like Precision Extraction and Delta Separations corroborate these findings through internal research and operational data. They report that extraction runs using frozen biomass resulted in significantly higher terpene concentrations and cleaner flavor profiles than dried material. These insights are leading innovation in hydrocarbon and cold ethanol extraction techniques.

Medical reviews also validate the efficacy of preserving a full spectrum of active plant compounds. A 2020 study from the Journal of Cannabis Research emphasized the importance of preserving the “entourage effect”—a synergistic interaction between cannabinoids and terpenes enhancing therapeutic benefits. This interaction is maximized when using fresh-frozen materials processed through cold chain methodology.

Industry Adoption and Leading Examples

Top-tier brands have already adopted cold chain processing as a cornerstone of their extraction strategy. Harborside Farms publicly touts its commitment to fresh-frozen flower to produce premium extracts. Similarly, 710 Labs focuses exclusively on cold chain workflows to deliver innovative, small-batch artisanal extracts.

These companies have capitalized on consumer preference for authentic flavor and whole-plant profiles, using their commitment to cold chain to build brand presence and justify top-shelf pricing.

Operational Considerations and ROI

Implementing a cold chain workflow involves multiple logistical considerations:

- On-site flash freezing capabilities immediately post-harvest

- Cold storage transport and warehousing systems

- Specialized extraction setups that accommodate frozen biomass

- Staff training on cold material handling procedures

Though capital intensive, the return on investment is significant. Higher yields, better flavor retention, and increased consumer demand translate into strong sales metrics over time. Moreover, in an industry increasingly governed by precise compliance testing, cold chain ensures consistency in cannabinoid and terpene profiling—an essential aspect of legal and commercial viability.

Conclusion

Cold chain processing is not just a trend in the world of cannabis—it’s rapidly establishing itself as the new gold standard in post-harvest handling. By preserving trichome integrity through rigorous temperature control, producers can retain the plant’s original chemical profile, enhance therapeutic efficacy, and develop concentrate products that stand out for their richness in flavor and aroma.

As scientific and consumer trends continue to underscore the importance of full-spectrum preservation, investing in cold preservation systems is becoming essential for producers aiming to generate high-end, compliant, and market-valued extracts.

References

– Volatile Organic Compound Emissions from Cannabis Drying and Curing – Frontiers in Plant Science, 2021

– The Case for the Entourage Effect – Frontiers in Plant Science, 2019

– Synergistic Interactions Between Terpenes and Cannabinoids – Journal of Cannabis Research, 2020

– Precision Extraction Solutions – Cold Chain Cannabis Blog

– Delta Separations – Cold Ethanol Extraction Insights

– Harborside Farms – Commitment to Fresh Frozen Extracts

– 710 Labs – Extraction with Intention

For more expert cannabis insights, visit Bluntys.com—Your Source for Elevated Knowledge.

Concise Summary

Cold chain processing in cannabis involves freezing cannabis immediately after harvest and maintaining low temperatures through extraction. This preserves trichome integrity, retaining cannabinoids and terpenes responsible for product quality, aroma, and therapeutic potential. Studies show significant compound loss occurs during traditional drying at room temperatures. By contrast, cold chain techniques offer superior batch consistency, purity, and potency. High-end producers and medical professionals now regard cold preservation as essential for full-spectrum extract production. Though more expensive to implement, the benefits in flavor, legality, and consumer demand make it a worthwhile investment for quality-driven cannabis operations.