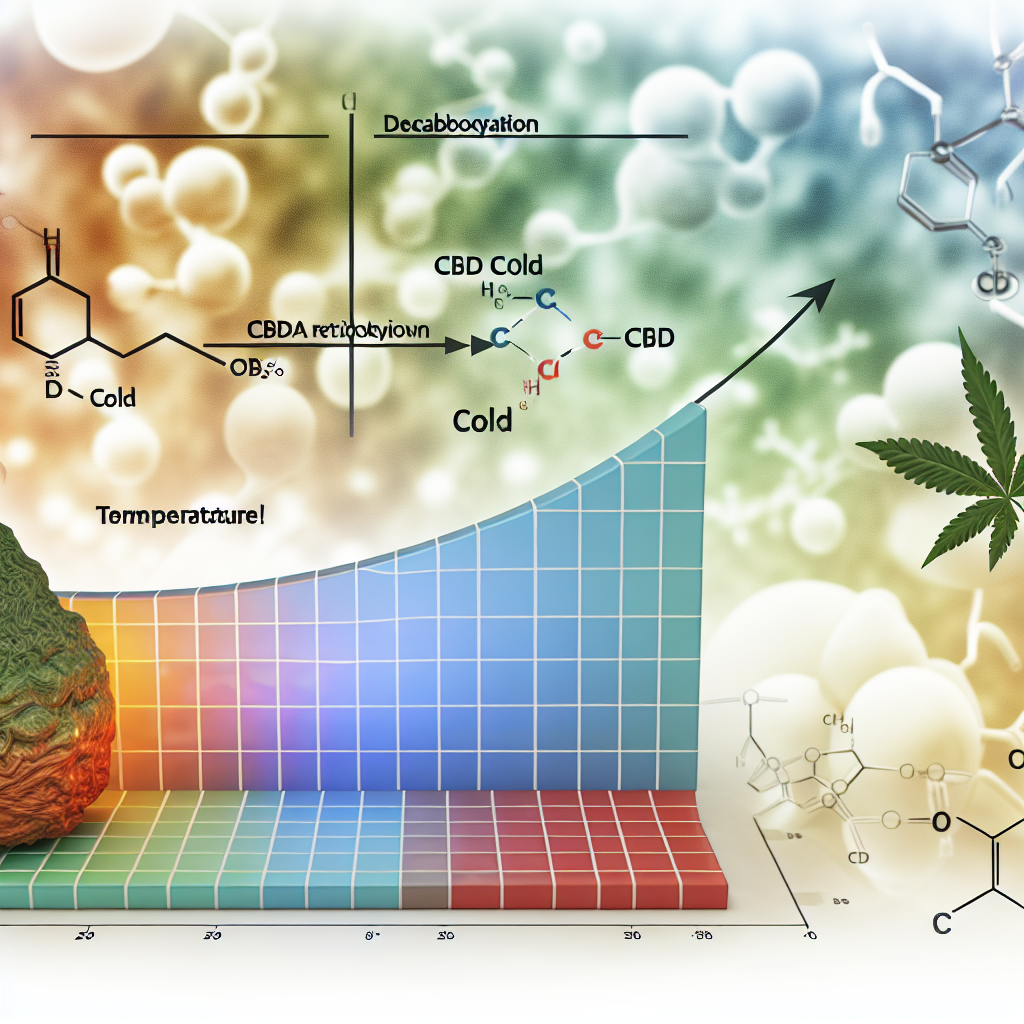

Kinetic Modeling of CBDA Decarboxylation: Optimizing Temperature for Maximum CBD Yield and Acid Retention

Introduction

As cannabis science advances, optimizing cannabinoid extraction and conversion becomes essential for producing consistent, high-quality therapeutic products. One of the most crucial processes is the thermal decarboxylation of cannabidiolic acid (CBDA) into cannabidiol (CBD). This transformation increases the compound’s bioavailability and medicinal efficacy in infused products such as edibles, topicals, and tinctures.

However, the decarboxylation process is a balancing act: insufficient heat results in incomplete conversion, while excessive heat degrades valuable cannabinoids and reduces overall potency. Traditional heating methods rely on empirical “rules of thumb,” often leading to over-processing and cannabinoid loss.

To improve accuracy and efficiency, the cannabis industry is now using kinetic modeling to define precise reaction rates and identify optimal temperature-time conditions. These models—based on first-order reaction kinetics—enable producers to predict and control chemical conversion processes, improving product consistency, maximizing yield, and preserving key acidic cannabinoids like CBDA, which may have unique anti-inflammatory and neuroprotective properties.

By leveraging kinetic modeling, the cannabis industry is transitioning to data-supported manufacturing techniques. These methods help regulate processes like temperature profiling, duration control, and utilize environmental methods—such as vacuum conditions or inert atmospheres—to reduce oxidative damage and protect cannabinoid integrity.

Features and Professional Studies

Kinetic modeling measures chemical reaction rates under varying conditions, particularly focused on temperature and time. In the case of CBDA decarboxylation, multiple studies have confirmed its behavior as a first-order reaction. This allows manufacturers to establish highly accurate thermodynamic parameters such as activation energy and rate constants, significantly improving upon generic time-temperature practices.

A pivotal study by Talaghat et al. (2020) used differential scanning calorimetry to analyze cannabinoid decomposition. Their findings suggest that optimal decarboxylation of CBDA occurs between 110°C to 120°C (230–248°F) over a 30–60-minute range. This minimizes the degradation of CBD into byproducts like cannabielsoin (CBE), which can dilute potency and diminish medicinal value.

A complementary study by Fitzgerald et al. (2020) from the University of Mississippi explored how real-time monitoring technologies like FTIR and HPLC can be used to track decarboxylation. These tools allow scientists to observe the transformation of CBDA in real time, preventing over-processing and maintaining the presence of acidic cannabinoids. This is particularly valuable for full-spectrum cannabis products that emphasize holistic therapeutic effects.

Further innovation is observed in a 2021 study published in Industrial Crops and Products, which explored vacuum-assisted decarboxylation. By reducing oxygen and pressure, this method accelerated CBDA conversion while suppressing degradation. Such strategies not only improve yield and purity but also reduce valuable terpene loss, offering enhanced product quality.

These studies exemplify the transition of cannabis science from anecdotal processing to controlled, replicable practices grounded in thermochemical research. The outcomes create a blueprint for applying scientific methods in cannabis extraction, helping facilities meet stringent regulatory standards while maximizing therapeutic efficacy and economic output.

Conclusion

The integration of kinetic modeling into CBDA decarboxylation marks a transformative shift in cannabis extraction science. By applying precise thermal and chemical knowledge, professionals can now accurately calibrate processing systems to maximize CBD yield while preserving bioactive CBDA. This scientific approach replaces outdated trial-and-error methods with predictive modeling tools, enabling consistent results and preserving therapeutic value. As research continues and advanced analysis tools become more accessible, kinetic modeling will likely become a foundational standard in the cannabis manufacturing industry.

Concise Summary

Kinetic modeling revolutionizes CBDA decarboxylation by identifying precise thermal conditions that convert CBDA into CBD with minimal degradation. Studies confirm it’s a first-order reaction, optimally occurring at 110–120°C within 30–60 minutes. Advanced techniques like FTIR, HPLC, and vacuum-assisted systems monitor and enhance the process. These methods increase CBD potency, reduce cannabinoid loss, and ensure product consistency, offering cannabis processors and formulators a data-driven pathway to high-quality production.